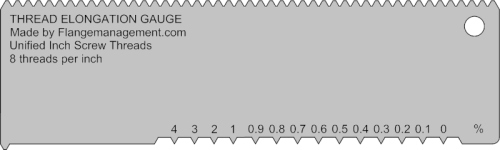

THREAD ELONGATION GAUGE

Thank you for purchasing the Flange Management Thread Elongation Gauge.

This precision instrument displays the measured elongation using a percentage scale.

Before use:

- Please read this instruction manual carefully and follow all operating procedures for safe and proper use.

- Keep this manual in an accessible place for future reference.

- If the gauge is transferred to another user, include this manual with the product.

- For any questions or service inquiries, please contact your dealer or the place of purchase.

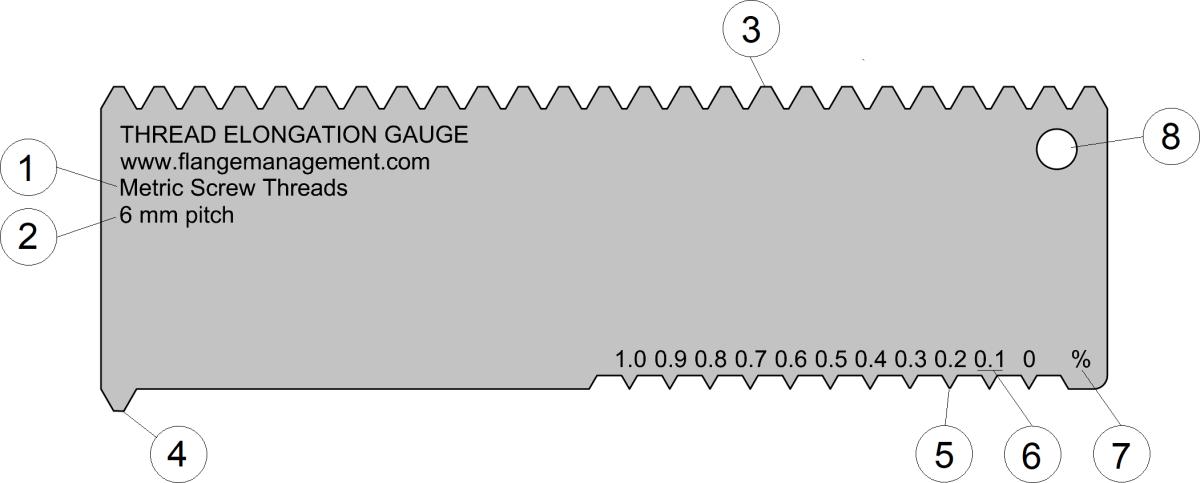

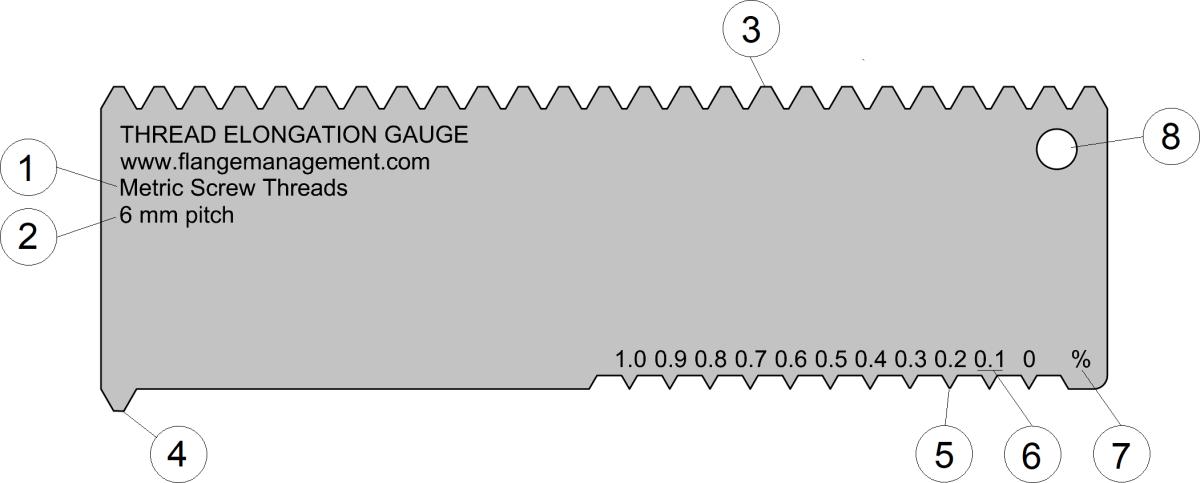

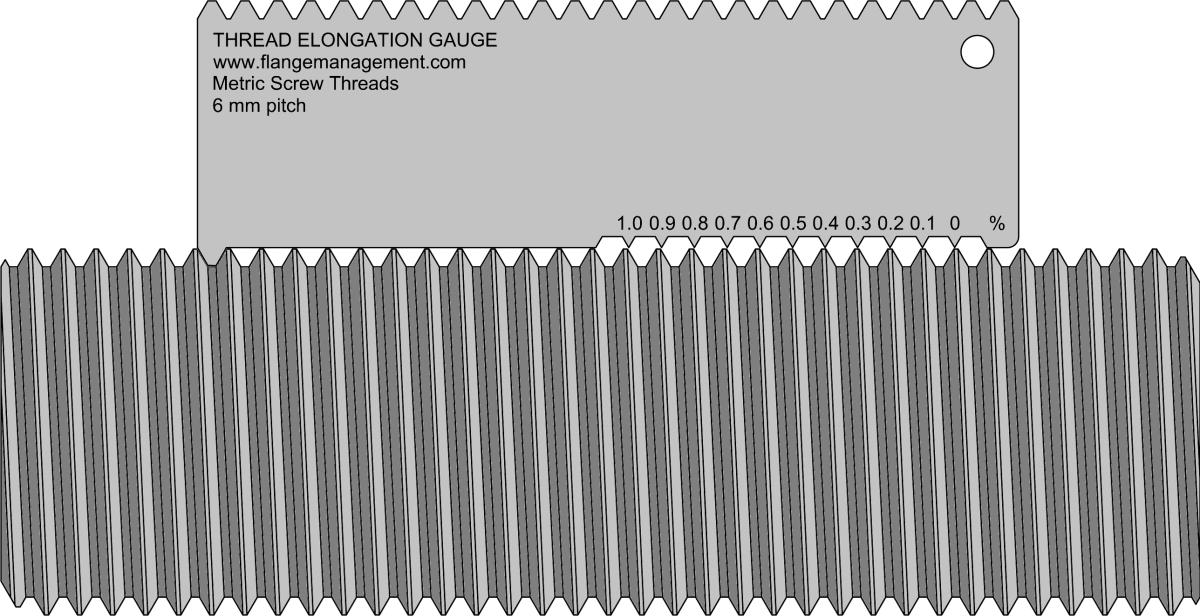

PART IDENTIFICATION

- Thread type – Indicates the standard thread form used (e.g., Metric or Unified).

- Pitch size – Specifies the thread pitch (e.g., 6 mm).

- Quick reference (zero percentage) check – Used for verifying zero elongation.

- Reference point – Baseline for measurement comparison.

- Value points – Markings corresponding to measured elongation values.

- Graduation scale – Displays the elongation percentage increments.

- Unit indicator – Shows that values are expressed in percent (%).

- Lanyard hole – Hole for attaching a cord or keychain.

SAFETY PRECAUTIONS

Always follow these operating procedures to prevent injury to yourself or others, and to avoid damage to property or the gauge.

Use only for measurement purposes.

- Using the gauge for any purpose other than measuring may cause damage or excessive wear.

Handle with care.

- Do not drop the gauge.

- Do not place it under heavy objects. Improper handling may cause deformation or loss of accuracy.

- Do not scratch or mark the gauge surface, for example by engraving or writing an ID number.

Sharp teeth – handle with caution.

- Careless handling may cause injury.

PREPARATION FOR USE

Before using the gauge, perform the following steps:

Wipe off any dirt, dust, or oil from the teeth and scale.

- Contamination on the measuring surfaces may cause damage or incorrect readings.

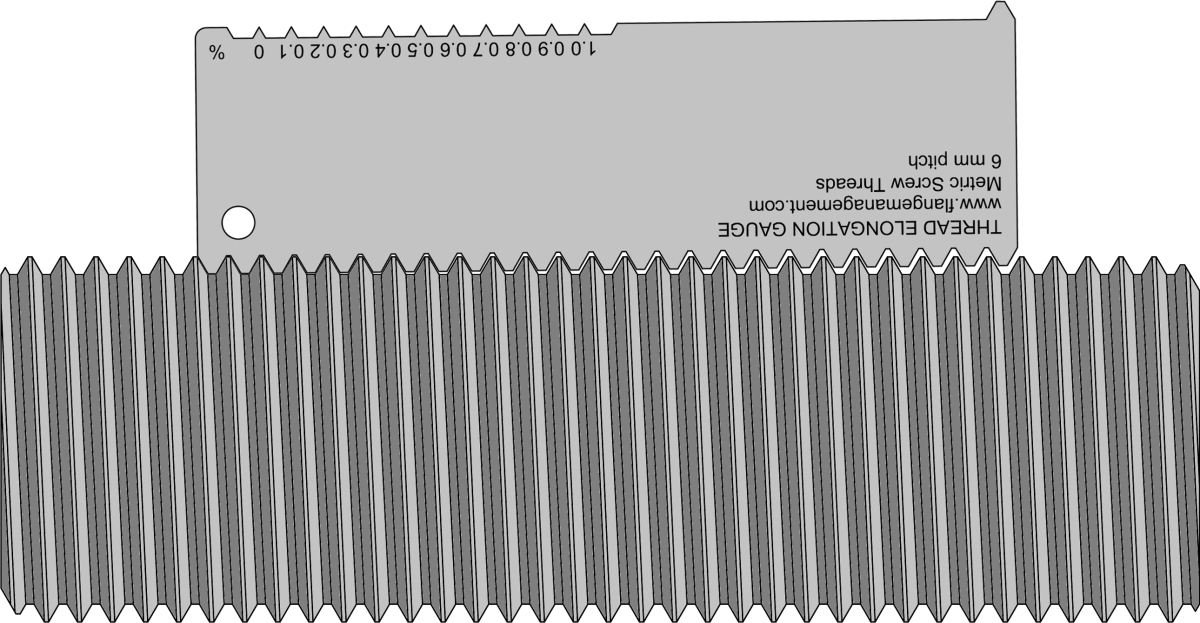

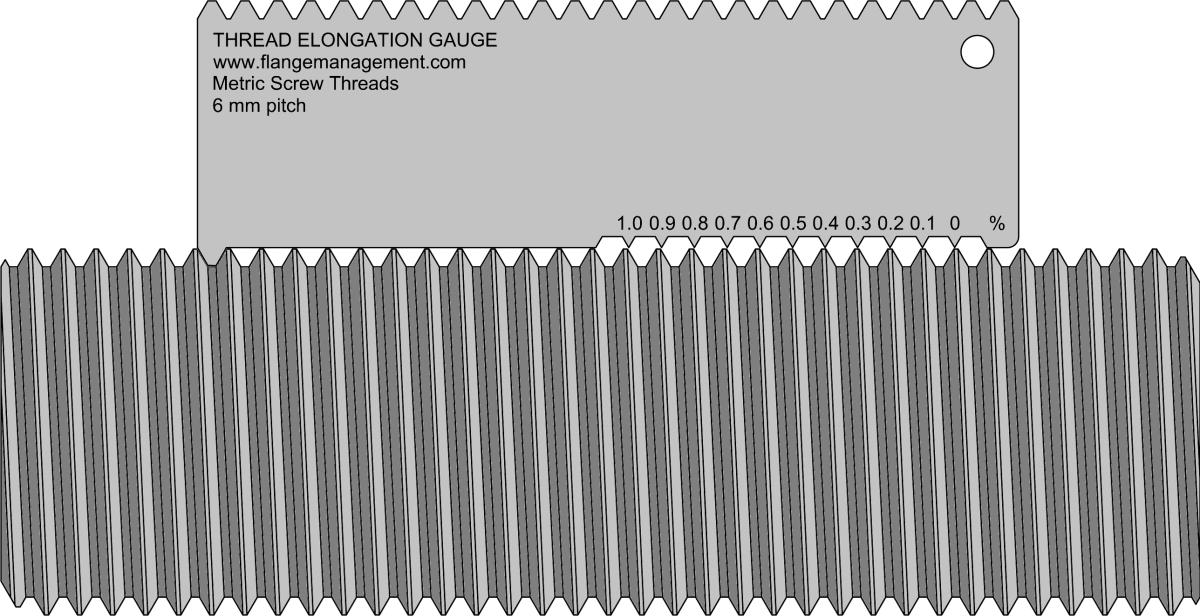

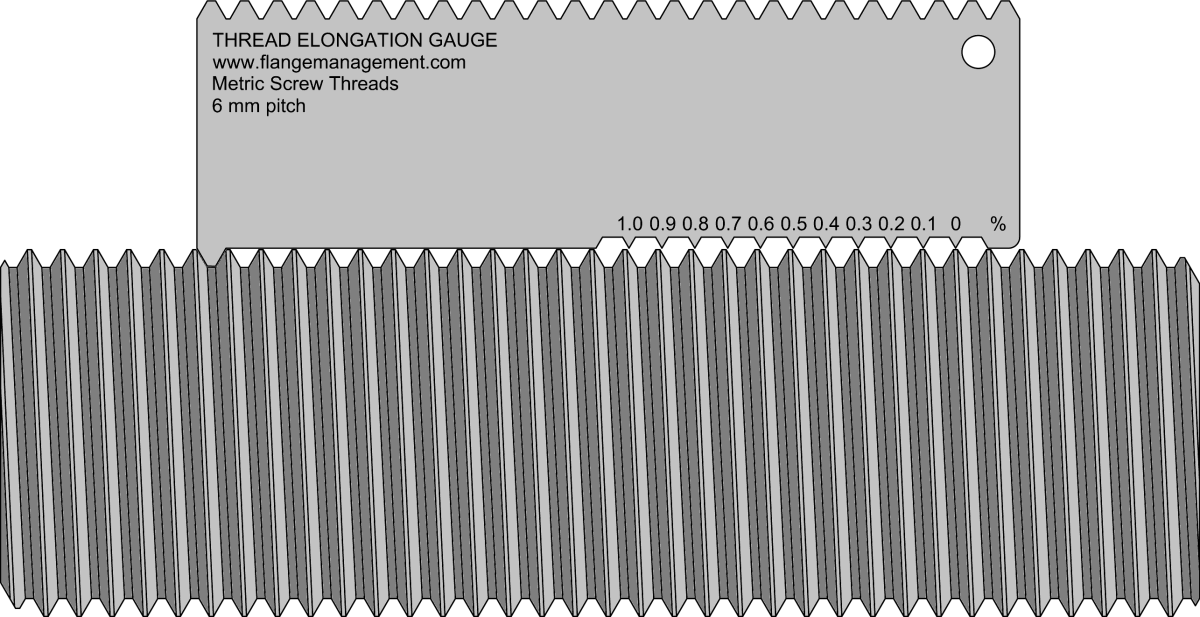

READING THE SCALE – Example 1

Quick check

- No permanent elongation is observed.

- The reading value is 0%.

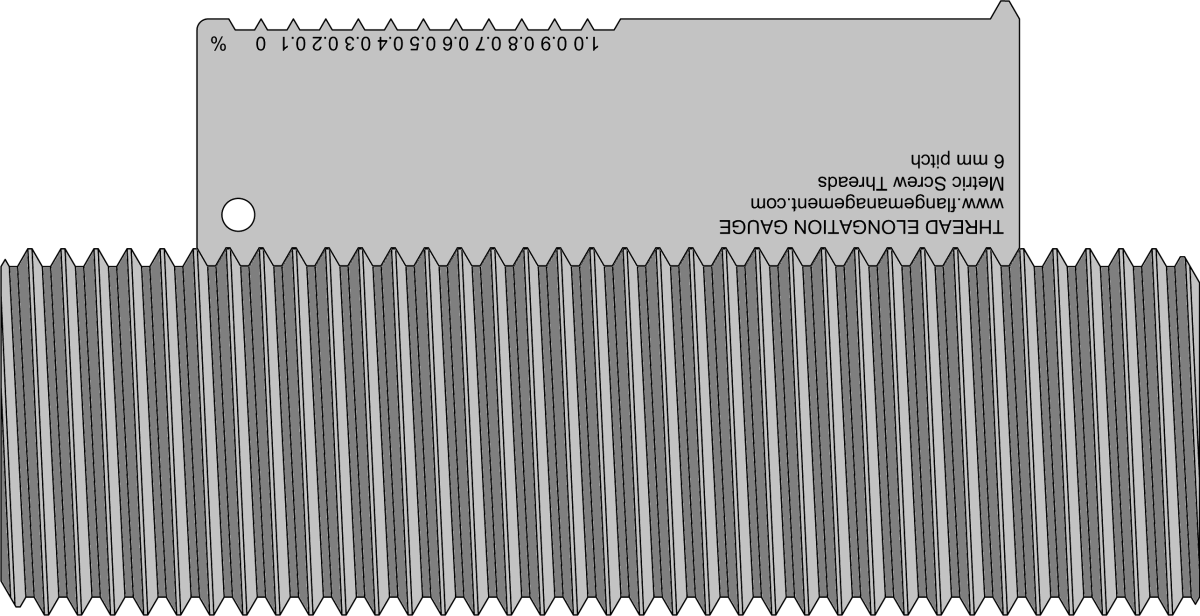

Double check

- Verify the reading by rotating the gauge 180°.

- Determine the measured value by reading the scale.

- The value is 0%.

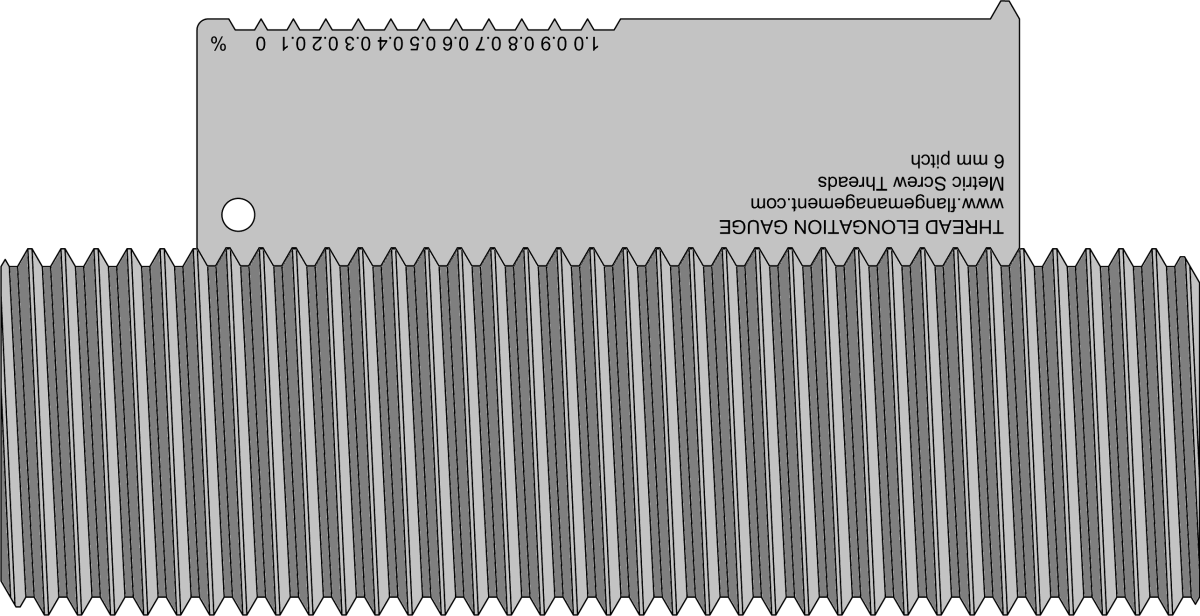

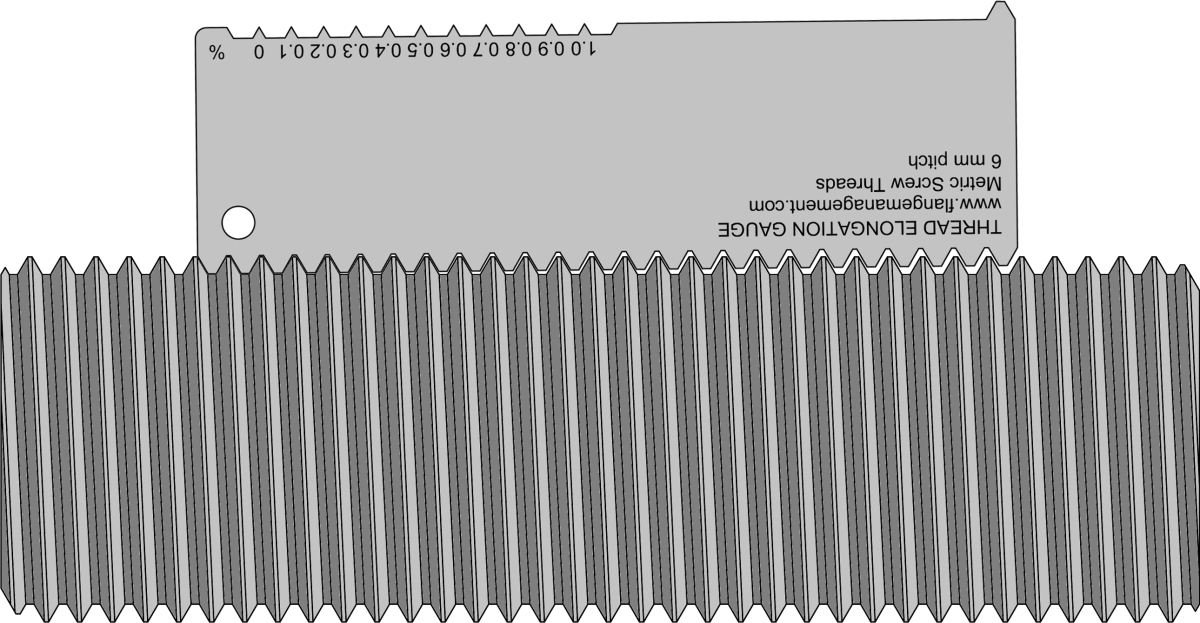

READING THE SCALE – Example 2

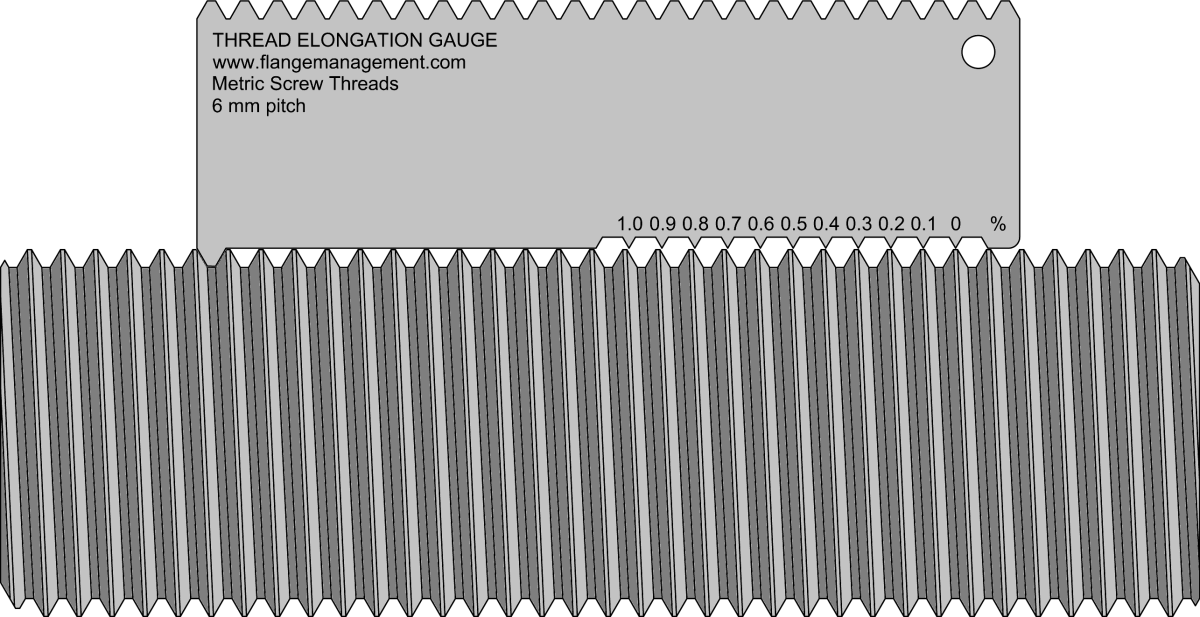

Quick check

- The gauge does not fit properly.

- A permanent elongation (set) has occurred.

- The elongation value cannot be determined.

Check the value

- Verify the reading by rotating the gauge 180°.

- Determine the measured value by reading the scale.

- The measured elongation is 0.2%.

SPECIFICATIONS

- Model No. Metric Screw Thread – 6 mm pitch

- Measurement Range: 0% – 1%

- Accuracy: ± 0.05 mm

- Material: Stainless Steel (SS304)Material