The Thread Elongation Gauge is a precision tool designed to detect plastic deformation in bolt threads caused by excessive tension, temperature fluctuations, or dynamic loading. It measures elongation in the central threaded section and provides both a percentage value and a clear pass/fail indication.

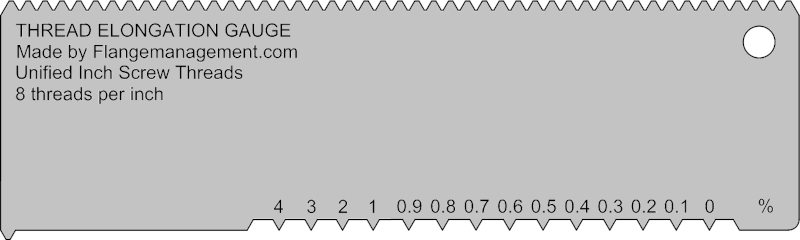

We deliver two versions: one with a 1% scale and one with a combined 0.1% and 1% scale.

The gauge measures thread elongation and helps detect the onset of plastic deformation. Although plastic deformation typically begins at around 0.2% strain (the proof stress criterion), the gauge itself measures actual elongation values such as 0.1% or 1%. Some companies use a 2% rejection limit, but this exceeds the conventional 0.2% yield-based threshold and is technically unjustified.

Thread form according to Unified Inch Screw Threads ASME B1.1

Thread form according to Metric Screw Threads ISO 724

Combined 0.1% and 1% scale.

1% scale